Rock phosphate YouTube

Dec 11, 2013· This video shows rock phosphate ore extraction process from our mine we are proud to visit our website for more details about our other products

WhatsApp)

WhatsApp)

Dec 11, 2013· This video shows rock phosphate ore extraction process from our mine we are proud to visit our website for more details about our other products

The production of superphosphate consists of three distinct steps. See the process flow diagram (Figure 4). Step 1 Phosphate rock blending and grinding Phosphate rock from different sources have different phosphate, fluoride and silica contents. These rocks are mixed in .

Phosphate Rock. The term phosphate rock (or phosphorite) is used to denote any rock with high phosphorus content. The largest and least expensive source of phosphorus is obtained by mining and concentrating phosphate rock from the numerous phosphate deposits of the world.

The next step in the phosphate fertiliser production chain is the chemical treatment, which may contaminate the environment in the vicinity of the plant (Kucera et al., 2007; othman and AlMasri, 2007). Wetprocess sulfuric acid acidulation is the most common technique for treating phosphate rock.

For Phosphate, flotation is, in general, very important to upgrading the phosphate rock and is employed in this study to beneficiate a 20% P2O5 feed content to a 3032% P2O5 content. The growing fertilizer industry has increased the demand for phosphate rock from which superphosphates are produced. The fertilizer market is very competitive.

Phosphate Beneficiation. Background. Definition of "Beneficiation": This is the second step in the mining process, after removal of the ore from the ground. Beneficiation is the technical term describing the industrial process of mechanically separating minerals from each other.

rock phosphate can become soluble (and available to plants) either by chemical weathering or through the actions of certain types of plants. The solubility also depends on rock type and the pH of the soil; phosphorus is most soluble when contained in sedimentary rocks as opposed to igneous rock, and when soil pH is between and

Apr 22, 2015· How to Make a PhosphateFriendly Garden ... Miners need to dig deeper and have to settle with lower quality phosphateore to keep up with increasing demand. ...

Process Description; Wet process phosphoric aciddihydrate: Phosphoric acid is produced by reacting sulfuric acid (H 2 SO 4) with naturally occurring phosphate phosphate rock is mined, dried, crushed until 60–70% of the rock is less than 150 μm in diameter, and then continuously fed into the reactor along with sulfuric acid.

Dewatering is an important process in mineral processing. The purpose of dewatering is to remove water absorbed by the particles which increases the pulp density. This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported easily, allow further processing to occur and to dispose of the gangue.

Apr 15, 2019· A more cautious figure of up to 3700 t U/a for the theoretically possible uranium recovery from phosphates is presented in [IAEA 2001]. This total assumes annual production of phosphate rock of 142 million tonnes per year yielding 66 million tonnes of concentrate.

provided a more consistent picture of phosphate rock formation, and indeed might guide the way to determine the position and extent of phosphate rock reserves thatare not currently economically viable. Various aspects of phosphorus geochemistry and phosphate rock formation have been considered before (, Sheldon, 1981;

Water quality, flotation equipment size and type, temperature, and ore body variation are just a few of the variables affecting the flotation process. Copper/Molybdenum Ore. The figure above is a simplified flow sheet showing the basic steps involved in a copper mill producing the byproduct molybdenum.

The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation, milling, and ore dressing ...

Oct 17, 2019· Next, the phosphate is extracted and purified. Few phosphate deposits are pure enough for the separation process to be eliminated. The specific process used to separate phosphate from other minerals varies based on the exact composition of the ore. In most cases, however, water is used to turn the rock into mineral slurry, from which a combination of screening and filtering processes can ...

There, highpressure water guns turn the material into a watery mixture called slurry, which is sent through pipelines to a processing facility, referred to as a beneficiation plant, where phosphate rock is physically separated from the sand and clay in the matrix. Learn more about the Florida phosphate mining process.

Nov 06, 2012· SBM Apatite Stone Crusher:Rock Phosphate Equipment,Apatite Mining Machine: . sand making process Ore Beneficiation Dressing Machine. Rock phosphate grinding plant,Phosphate grinding mill in Pakistan . Apatite Mineral Processing; . During beneficiation, phosphate particles are separated from the rest ofthe ore. . Phosphate Crushing Process

In Florida, after the phosphate rock is extracted, the ore is dumped into a pit at the mine site, and highpressure water guns turn it into slurry. The slurry is pumped to a beneficiation plant. At the processing plant, the slurry mixture goes through a twostep process to separate the phosphate rock from sand and clay particles.

The Mining Process. The mining process in Florida begins with a field study to determine the location and density of the phosphate deposits. Information like the location, size, and shape of the ore is determined to focus the mining effort.

steps for each. Phosphate Rock Mining ... In this process, phosphate fines are heated in a rotary kiln to incipient fusion. The tumbling in the kiln causes the material to cohere and form spheroidal agglomerates. A final ... Energy and Environmental Profile of the Mining Industry Phosphate .

Jul 07, 2015· Recently I visited a RockPhosphate Plant wherein I saw the Flotation Process in Operation. Here is small video of the Flotation Process. For .

How Phosphate is Recovered Phosphate rock is usually found 1550 feet beneath the ground in a mixture of phosphate pebbles, sand and clay known as phosphate "matrix." The sandy layer above the matrix, called the overburden, is removed using electrically operated draglines. ... Water management during the mining process is an extremely important ...

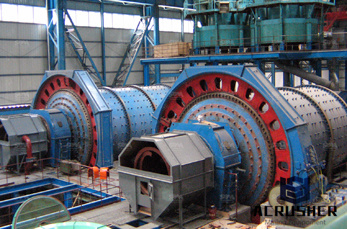

Phosphate Rock Processing Process Description15 The separation of phosphate rock from impurities and nonphosphate materials for use in fertilizer manufacture consists of beneficiation, drying or calcining at some operations, and grinding. The Standard Industrial Classification (SIC) code for phosphate rock processing is 1475. The ...

Feb 06, 2001· 8. The method of claim 7 in which the hydrolysis of step (b) is carried out by treating such calcium sulphate with an alkali metal hydroxide such as sodium hydroxide to form calcium hydroxide and the alkali metal sulphate. 9. The method of claim 1 wherein calcium phosphate rock ore is utilized as source of calcium phosphate.

WhatsApp)

WhatsApp)